The dairy industry is the backbone for the economy of many countries in the world and accordingly Contamination of dairy products and milk powder with spore formers is a concern mainly due to the potential for spoilage leading to undesirable product quality.

Aerobic Plate Count in Milk Powder

Contamination of milk powder with spore formers is a concern mainly due to the potential for spoilage leading to undesirable product quality. It is important to ensure that all milk powders produced are free from both spoilage and pathogenic bacteria. Standard laboratory tests are used to determine the quality of the products and ensure the cleanliness of the processing lines.

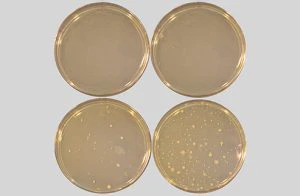

obviously bacteria can’t be seen with eyes. The bacteria grow in colonies that allow us to see and count them. These colonies start as a single bacterial cell that multiplies thousands of times until they grow to an amount that forms a colony. Each colony is counted as 1 bacterium (colony forming unit) or CFU. The procedure that allows microbiologists to estimate the population density in a liquid sample by plating a very dilute portion of that sample and counting the number of colonies it produces is APC.

Agar as a growing medium for bacteria

To be able to see the bacteria easily, we grow the bacteria on something called agar using special nutrients. Agar is a gel-like substance derived from red algae. It is commonly used in the lab as a solid growth medium for bacteria and other microorganisms. This is because agar is non-toxic, inexpensive, and provides a stable environment for bacteria to grow in. Each cell forms a visible colony when mixed with agar containing the appropriate nutrients.

Mesophilic aerobes in milk

The mesophilic aerobes (MA) are indicator microorganisms often used to verify the microbiological quality of milk and dairy products, because they provide valuable information about sanitary and hygienic conditions of milking, storage, and processing, and also suggest the presence of pathogenic microorganisms. Mesophilic aerobes are able to grow between 20 and 45°C , with an optimum growth temperature of 32°C, and include the majority of spoilage and pathogenic microorganisms associated with milk and dairy products.

Total plate count (TPC) test

The total plate count involves the enumeration of aerobic, mesophilic organisms thriving under moderate temperatures of 20-45°C in aerobic conditions. This encompasses aerobic bacteria, yeast, molds, and fungi growing in the designated agar. This method is used for enumerating the total count of aerobic bacteria on plates.

Standard plate count measurement

The aerobic plate count (APC), also known as standard plate count (SPC), aerobic mesophilic count, total plate count, or aerobic colony count, is utilized to estimate the bacterial population in a food sample. It does not evaluate the entire bacterial population or indicate differences among bacterial types in a food product. Instead, it provides an approximation of the numbers of microorganisms capable of aerobic growth at mesophilic temperatures.

The APC may be employed to assess sanitary quality, sensory acceptability, and compliance with good manufacturing practices (GMPs). Its results can offer a food processor insights into the quality or handling history of raw materials, food processing and storage conditions, and the handling of the finished product. Additionally, it can be used to determine the shelf-life or potential sensory changes in a food product.

In Hiroland, our milk powder, made from high-quality milk and adhering to rigorous quality control standards, possesses a protein content exceeding 34% and an APC of less than 10,000, positioning Hiroland’s industrial milk powder favorably in comparison with high-quality EU producers.

The standard plate count procedure

The Standard Plate Counts test assesses both total aerobic bacteria and total mold and yeasts. Plate counts can be conducted using membrane filtration, pour plates, or spread plate methods.

The plate count method

Plate counting is a fundamental microbiological technique employed to ascertain the quantity of viable (living) cells in a sample. Its execution involves several meticulous steps, all of which are crucial for obtaining accurate results. The use of aseptic technique throughout the process is essential. Aseptic technique encompasses a set of procedures designed to prevent sample contamination, such as handling tubes at an angle, flaming bottle lids, and using sterile pipettes, among others.

The anaerobic plate count

The anaerobic plate count provides an estimate of the number of viable anaerobic micro organisms in food and is affected by the type of medium used and the length and temperature of incubation.

The difference between total plate count and total viable count methods

The difference between total plate count and total viable count methods lies in what they enumerate. The total plate count quantifies both living and dead microbial cells, whereas the total viable cell count enumerates only the living cells. Additionally, the viable count is a growth-based technique, in contrast to the total cell count method.

Conclusion

The aerobic plate count (APC), also referred to as the standard plate count, aerobic mesophilic count, total plate count, or aerobic colony count, is founded on the assumption that each microbial cell will form a visible colony when combined with agar containing the appropriate nutrients. It does not represent the entire bacterial population; rather, it is a general test for organisms that thrive aerobically at mesophilic temperatures (25 to 40°C; 77 to 104°F). Furthermore, a low APC result does not guarantee the absence of pathogens in the product or ingredient.

Conducting an APC test provides an indication of bacterial contamination that may occur during the collection, processing, handling, or packaging of materials. The APC can be utilized to assess sanitary quality, sensory acceptability, compliance with good manufacturing practices, and to a lesser extent, as an indicator of safety.

For inquiries or to contact the Hiroland, please refer to the Contact section.

Read More: Comprehensive Guide to the Milk Powder Production Line: Steps and Benefits

Read More: Testing for total bacteria in dairy powder – Comparison of test incubation temperatures

1 thought on “Understanding the Significance of Aerobic Plate Count in Milk Powder Quality Assurance”

Thx for the different recommendations I have figured out from your weblog.