Here we aim to dive into the subject of the Art of Butter Making, a solid dairy product, made of cream by separating the butterfat from the buttermilk.

Tracing the butter making process from Sumerian tablets to modern kitchens

Butter, a remarkably versatile ingredient for both cooking and baking, effortlessly enhances any dish with just a small amount. Packed with essential nutrients like vitamins A, E, and B12, along with beneficial compounds such as butyrate and alpha-linolenic acid, it offers a nutritional boost. Despite its high fat and calorie content, butter is relatively low in omega-6. When consumed in moderation and as part of a balanced diet, especially alongside other heart-healthy fats, butter can be a valuable addition.

Evidence of early dairy production traces back to a Sumerian tablet from 2,500 BCE, illustrating the milking of cows and the process of butter-making. This discovery played a significant role in shaping human culture.

Butter essentially comprises the fat of milk, typically made from sweet cream and salted. However, unsalted (sweet) butter can also be produced from acidulated or bacteriologically soured cream. By the 19th century, butter was crafted from cream left to naturally sour. The cream was skimmed from the milk’s surface and transferred into a wooden tub, where butter making was manually performed using churns. The natural souring process was susceptible to contamination by foreign microorganisms, often resulting in spoiled butter. Today’s commercial butter making reflects advancements in hygiene, bacterial acidification, heat treatment, and machinery, stemming from accumulated knowledge and experience over the years.

Overview of the Art of Butter Making Process

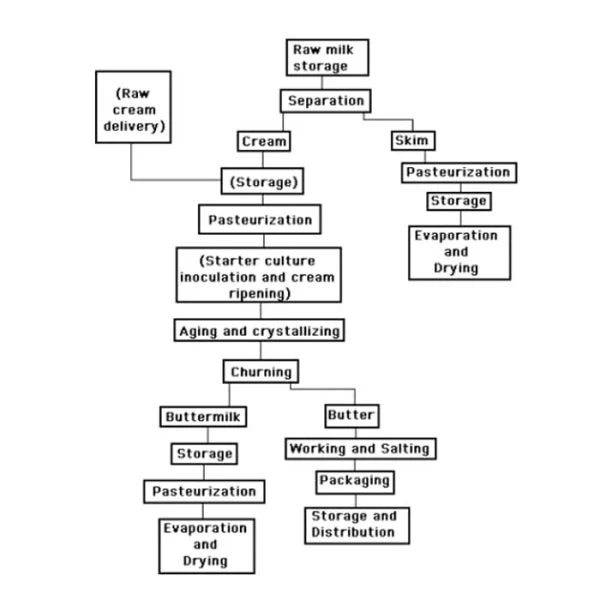

The art of Butter making Process has been shown in following Flowchart,

The art of butter making process involves multiple stages. Cream, sourced either from a dairy or separated by the manufacturer, must meet specific quality criteria. After preheating and analysis, the cream undergoes pasteurization to eliminate enzymes and microorganisms. If ripening is desired, cultures are added to achieve optimal pH levels. Aging then occurs to develop flavor and crystalline structure. Following this step, the cream is transferred to a churn, which is a large mechanical device designed to agitate the cream vigorously. Churning breaks down fat globules, separating butter grains from buttermilk. After thorough churning, the resulting solid mass is carefully drained of excess buttermilk and then extensively washed to remove residual buttermilk. Salt may be added for flavor and preservation, followed by vigorous working to ensure homogeneity. The final product is packaged and stored in cold storage. The resulting product is industrial butter, which can be further processed and distributed for various culinary and commercial applications.

Fats Definitions and Standards

Milkfat

Milkfat refers to the lipid components naturally present in milk from cows and is commonly found in various milk-based products, predominantly consisting of triglycerides.

Butterfat

Butterfat is essentially synonymous with milkfat and encompasses all fat components in milk that can be separated through churning.

Anhydrous Milkfat

Anhydrous Milk fat (AMF) is the commercially prepared extraction of cow’s milkfat, available in bulk or concentrated form, comprising 100% fat but not necessarily containing all lipid components of milk.

Butteroil

Butteroil, another term for anhydrous milkfat, follows conventional fats and oils terminology, where “oil” and “fat” differentiation is based on whether they are liquid or solid at room temperature, albeit somewhat arbitrary.

Butter

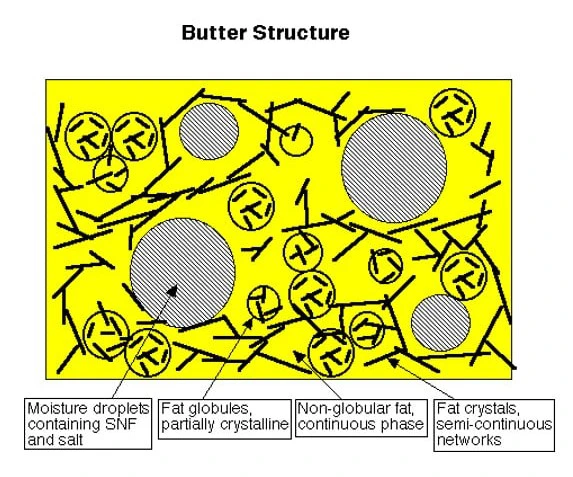

Butter is a water-in-oil emulsion consisting of over 80% milkfat, along with water in small droplets, possibly some milk solids but without salt (referred to as sweet butter). Its texture is achieved through processing at specific temperatures, establishing a desired fat crystalline network for smoothness. Butter serves various purposes as a spread, cooking fat, or baking ingredient.

Typically, salted butter contains fat (80 – 82%), water (15.6 – 17.6%), salt (about 1.2%), along with protein, calcium, phosphorous (about 1.2%), and fat-soluble vitamins A, D, and E.

Quality butter should have a uniform color, dense texture, and a clean taste. Its water content should be dispersed in fine droplets, giving it a dry appearance, and its consistency should be smooth for easy spreading and quick melting on the tongue.

Insights into Different Types of Butter

Sweet Cream Butter

• Made from fresh cream, either salted or unsalted.

• Produced by churning pasteurized cream until buttermilk separates from butterfat.

• Neutral, creamy flavor with a smooth texture.

• Versatile for baking, cooking, and spreading on bread.

Cultured Butter

•European-style butter made by fermenting pasteurized cream with bacterial culture.

•Has a slightly tangy flavor due to fermentation.

•Offers depth and complexity to dishes, particularly in French cuisine.

•May have a more granular texture.

Salted & Unsalted Butter

•Salted butter contains 1-2% salt by weight; unsalted has no added salt.

•Salted butter has a longer shelf life (up to two months refrigerated).

•Using unsalted butter allows better control of saltiness in dishes.

Hiroland Creamery Butter, boasting 82% butterfat, is available in a range of forms, including both salted and unsalted varieties. Unsalted sweet cream butter is favored in baking to regulate the salt content in recipes and in various industries, while salted butter is frequently used as a table spread.

European & American Butter

•American butter has a minimum butterfat content of 80%, often with additional components like water and milk solids.

•European-style butter sold in the US has a minimum butterfat content of 82%, offering richer flavor and texture.

•Higher butterfat content in European-style butter enhances quality and taste compared to American butter.

For inquiries or to contact the Hiroland, please refer to the Contact section.

Read More: Butter and Dairy Fat Spreads

Read More: Comprehensive Guide to the Milk Powder Production Line: Steps and Benefits