Dairy solids in ice cream formulation play a defining role in shaping texture, mouthfeel, and product stability of today’s competitive frozen dessert industry. Behind every scoop lies a precise balance between ingredients such as skimmed milk powder (SMP) and buttermilk powder (BMP) — both of which determine not only flavor and body but also production cost-efficiency and consumer satisfaction.

Which ingredient provides better results — SMP or BMP?

For food technologists and industrial ice cream manufacturers, one question often arises:

Which ingredient provides better results — SMP or BMP?

Recent research and commercial evidence reveal that the best answer may be a functional blend of both, leveraging the advantages of each to optimize dairy solids performance.

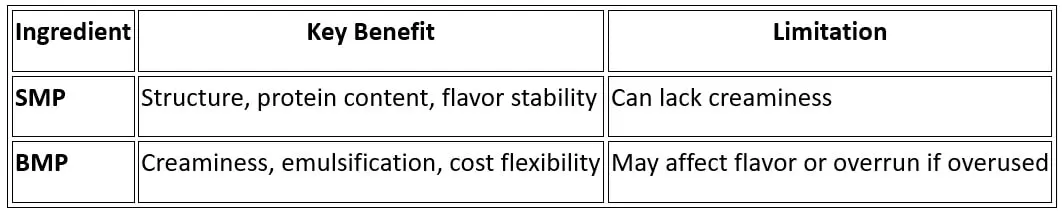

Skimmed Milk Powder (SMP)

• High in protein and lactose, contributing to overrun stability and body.

• Maintains a consistent dairy flavor with reliable performance.

• Ideal for balancing creaminess and aeration in frozen dessert production.

Buttermilk Powder (BMP)

• Rich in milk fat globule membrane (MFGM) components and phospholipids.

• Acts as a natural emulsifier, enhancing creaminess and fat dispersion.

• Often more cost-effective than SMP, depending on market conditions.

According to patents such as EP0242056, AU2021107295, and US20090074932, both SMP and BMP are recognized as functional milk solids in soft-serve and industrial ice cream applications. This confirms that dairy solids in ice cream formulation can be strategically optimized through blending rather than substitution.

What the Science Reveals About Ice Cream Dairy Solids?

Recent scientific studies and industrial trials provide compelling evidence on the evolving role and performance of dairy solids in ice cream formulation, particularly highlighting the growing value of buttermilk powder (BMP) alongside skimmed milk powder (SMP). Research published in the Journal of Dairy Science shows that BMP’s naturally occurring phospholipids significantly enhance fat emulsification, leading to smoother mouthfeel and superior creaminess compared to SMP-based mixes. A 2024 study by Kiełczewska et al. in MDPI Foods further demonstrated that partially replacing SMP with BMP improves viscosity, melting resistance, and overall body smoothness, delivering a more stable and indulgent texture. Supporting these findings, Ivanova (2024) reported that ultrafiltered buttermilk can functionally replace certain stabilizers, maintaining consistency while reducing formulation costs — a valuable advantage for large-scale manufacturers. Moreover, Szkolnicka et al. (2020) confirmed that BMP-enriched ice cream formulations not only achieve premium sensory attributes comparable to traditional mixes but also contribute to greater sustainability by utilizing buttermilk streams efficiently. Collectively, these studies reaffirm that BMP is far more than a by-product; it is a functional, cost-effective, and high-value dairy ingredient that enhances the structural and sensory balance of modern ice cream formulations when strategically combined with SMP.

Why a Hybrid SMP + BMP Blend Works Best?

In industrial production, balancing dairy solids in ice cream formulation means weighing structure, flavor, cost, and supply chain stability.

A hybrid formulation combining skimmed milk powder (SMP) and buttermilk powder (BMP) offers a synergistic approach to optimizing dairy solids in ice cream production, delivering multiple functional and economic advantages for manufacturers. By merging the structural stability and protein contribution of SMP with the emulsifying power and phospholipid richness of BMP, such blends achieve superior texture, smoother mouthfeel, and enhanced creaminess — key attributes that drive consumer satisfaction. From a financial perspective, hybrid SMP + BMP systems provide greater cost-efficiency, allowing formulators to adjust ingredient ratios based on real-time market fluctuations in dairy raw material prices without compromising quality or performance. Technologically, the improved emulsion stability derived from BMP’s milk fat globule membrane (MFGM) components ensures more uniform fat distribution and melt resistance, contributing to a richer and more consistent eating experience. Furthermore, integrating BMP into the formulation aligns strongly with sustainability objectives by valorizing buttermilk — a traditional dairy by-product — into a high-value functional ingredient, reducing waste and promoting resource efficiency across the dairy supply chain.

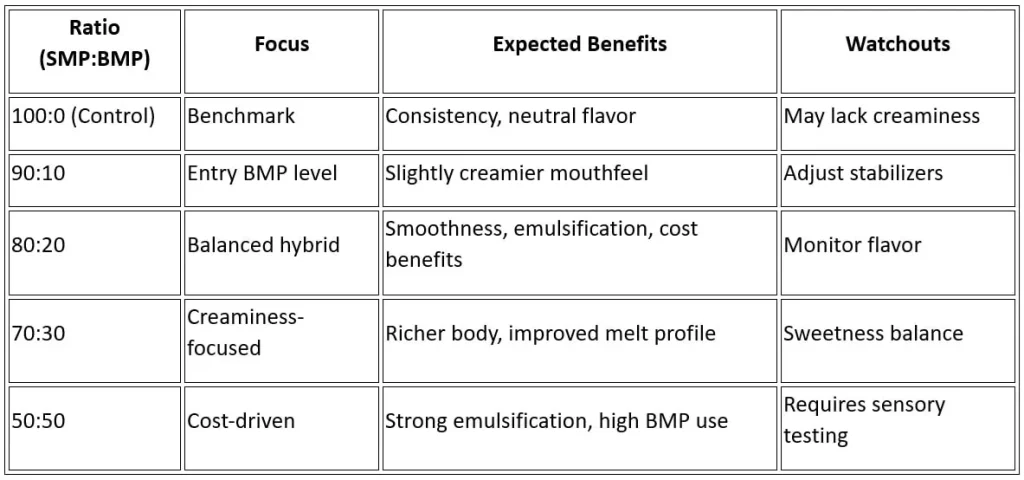

Suggested R&D Ratios for Ice Cream Dairy Solids Trials

Hiroland recommends pilot testing the following SMP:BMP ratios to identify the optimal combination of dairy solids for specific market needs:

Recommended R&D Protocol

1. Define Objectives: Cost reduction, creaminess, or stability.

2. Prepare Mixes: Maintain ingredient consistency across pilot batches.

3. Control Processing: Use identical pasteurization and freezing conditions.

4. Test Functional Properties: Measure overrun, viscosity, melting rate, and firmness.

5. Sensory Evaluation: Conduct panel tests to assess flavor, texture, and mouthfeel.

6. Cost Analysis: Compare SMP/BMP pricing and yield efficiency.

7. Formula Optimization: Scale up the best-performing ratio for production.

The Business Value of Balanced Dairy Solids in Ice cream

For B2B ice cream producers, SMP + BMP blending provides measurable value:

• Functional excellence: Enhanced body, stability, and melt resistance.

• Economic flexibility: Adaptable to regional price shifts.

• Product innovation: Distinct textures and creamy profiles.

• Sustainability: Full utilization of buttermilk by-products.

At Hiroland, we help R&D teams create science-based, scalable dairy solids formulations that optimize both performance and profitability.

Final Thoughts

As demand for premium frozen desserts grows across global markets, achieving the right balance of dairy solids in ice cream formulation is essential. Combining SMP and BMP offers a science-backed path to richer textures, greater stability, and improved cost control.

At Hiroland, we partner with food technologists and manufacturers worldwide to deliver customized dairy ingredients that meet the highest international standards.

Ready to test SMP/BMP blends in your ice cream line?

Contact our application experts today or visit www.hiroland.com to learn how we can support your next innovation.

Read More: The Buttermilk Role in Perfecting Ice Cream Delight

Read More: Buttermilk ice cream—New method for buttermilk utilization